Hi Jimmy,

Haven’t had this error.

I live north of Sydney Australia and we have plenty of days over 90f.

I roast in a cooler shaded room ,about 28c but face the exhaust outside through a door so the room doesn’t heat up.

I roast 800 g as my standard roast and only need the top heat for 2-3 minutes.

Highest sensor temp is about 62 c.

I used to notice major differences with roast profile from summer to winter when I used a hot top but haven’t seen this with the Bullet.

Enjoyed the discussion and ideas.

800g + batches are more stable.

But I run into either weak or scorched flavors. With a lower fan, chaff build up and steam are an issue. And with a higher fan, things clean up, but flavor is fairly tame, and tastes a bit raw.

Just seems to be an issue across the board. With smaller 225g batches, the fan doesn’t have to be so high, so occasionally one of those smaller light roasted batches are nice, but they are temperamental, so no two batches end up the same, even if the curve looks spot on.

The error was fixed by a firmware upgrade for me. Now my IGBT1 sensor doesn’t error until 100C. As long as I have a fan on the under side of the roaster, I don’t get the error. This has made an improvement on being able to roast, as I now have access to P8 and P9. However, I’m still navigating the larger batch sizes.

I can get nice flavors, but they are weak, and often accompanied by graham or paper. Shortening the development time to 2min doesn’t help entirely. Just tastes less developed and papery, as opposed to developed and papery. So, at least there is a bit more acidity and sparkle, but does not brew well.

I’ve bought nice beans, and those become more drinkable, but only by virtue of the bean, as the roast is still not exemplary. Still lower flavor and either crazy or darker and flavorless. If I push it harder into dev, I just kill the sweetness and acidity, but if I hold back, I get grass and paper. On nicer beans, they are more forgiving to the roast, and have a way of tasting nice regardless of the roast style, but it still feels like a waste of $15/lbs green.

I just had a thought about wether there are differences in p9 etc between 110 or 240 volt versions ?

Yes, there are.

I’ve had tech support tell me there isn’t and some tech support tell me there is.

But you notice when Aillio team introduces a recipe or roasting approach, they note to adjust for 240 vs 120v

120v does still push through the tiny 1Kg batch easily enough, but the electronics are likely running a little more strained in a way?

I wonder if a warmer room causes the 120v electronics to run less efficiently?

Running into this issue with 0004 after upping batch sizes from 750g to 1kg trying to do back to back in a 65 deg F kitchen. Got 3 1kg roasts before 0004 shut me down and wouldn’t stop until I put the roaster on cool down.

Monitor the IGBT1 reading in the info panel (see the screen shot in one of the posts above), and make sure your RT software is running the latest version. When you roast 1kg batches things get hot. I (as well as many others) use a fan of some sort to move the air under the roaster to keep things cooler so that the IGBT1 reading doesn’t go red.

You can also increase F setting to cool things down a bit.

I have successfully roasted 6kg back to back at ambient 67F temp in my kitchen.

Cool, thank you @blacklabs , that tracks with the info support sent me.

I’m now updating to the beta 610 version and will need to go grab a little fan somewhere; support also mentioned in conclusion “That said, maintaining the exhausting airflow is the ultimate solution,” so I think I also needed to empty the chaff collector after that third roast - after 3 roasts the chaff collector was about half full so that seems like a reasonable time to empty it to clear the airway.

I do it after every 2 roasts - I just use a crevice tool of my vac to get as much out as possible with out opening it up.

Hi Jimmy, I’m in Sydney and in Summer often get temperatures above 30 deg C.

If I roast at these temperature the Bullet seems to have a problem during the roast. It will get to 160 deg then all the heat comes off and the ROR will drop to 0 before it can start heating the roast again. Thus I need to wait until late at night for the temp to drop below 29 deg to roats.

Brad

That is about where my old induction board had issues too. The replacement board is not as sensitive. However, I still avoid excessive heat because the plastics seem to warp and recede.

A few thoughts…

The issue is the ambient temp, of course, but the reading which is causing the issue is IGBT1 temp in the “i” list of Bullet stats. When that temp gets somewhere above 80°-83°C the Bullet power board starts throttling power. You can affect the reading by

- lowering power (probably not what you want to do as it affects the profile but then that’s exactly what the Bullet power board is doing on its own),

- add cooling to your roasting environment,

- add external cooling fan under the Bullet directed at the power board.

There was a f/w mod a couple years ago (?) which keeps the cooling tray fan spinning during a roast in order to provide a little cooling for the power control semiconductors. I tried a separate fan which was a little more effective than the cooling tray fan but it wasn’t a magic cure.

The best solution is the brute force approach of providing cooler air to your roasting space. I settled on a ‘portable’ (roll around) swamp cooler (evaporation cooler), but then I’m in southeast Arizona desert which is dry! (typically 20-30% humidity or lower). If your humidity runs much above 50-60% the swamp cooler won’t be all that effective and you’ll have to consider refrigerated air conditioning. And with the room a little cooler the additional cooling fan under the power board could prove more effective,

You could also experiment with roasting smaller batches which is what I tried first. It’s important to keep the same profile (time-to-1Cs, time-to-2Cs and time-to-drop targets). With a smaller batch you may be able to drop Power settings a small amount and still manage the Time-to-event of your profile. If yours is a commercial operation then smaller batches probably aren’t a realistic option.

There are probably a few other things to try so this is just a starter-list. I think I recall several posts about an additional power board cooling fan (was that you @billc ?).

Bruce

Hey Bruce and @bradnl4e ,

I tried a few things to help keep the Bullet working and not shutting off due to an overheat condition.

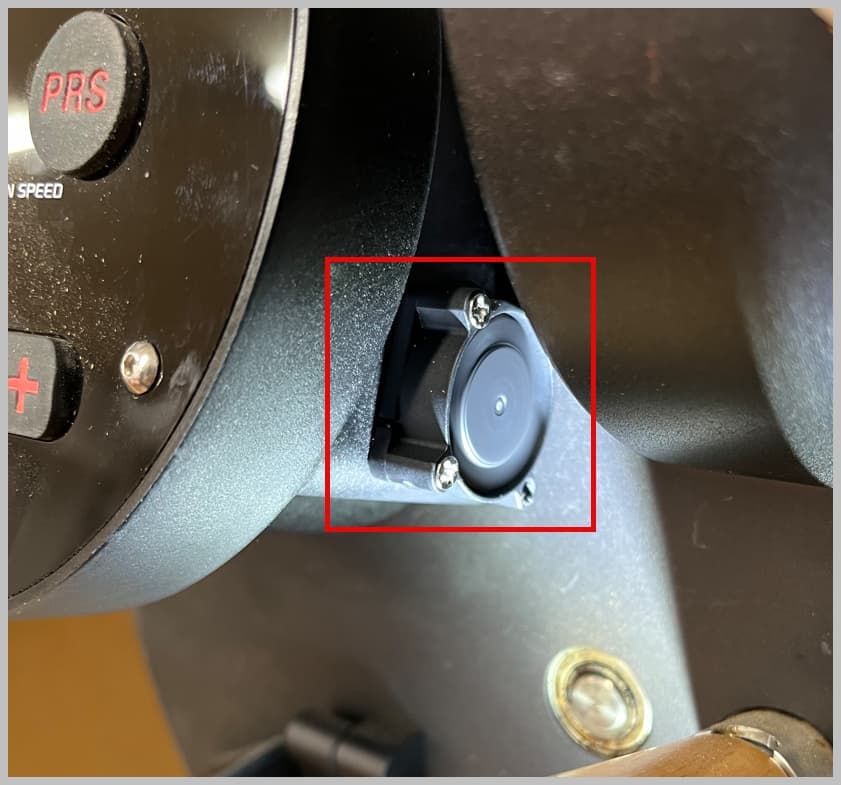

From my understanding, there are 2 areas that can benefit from extra air circulation. One is on the belly of the beast. Most people that have heat issues will start by aiming a small fan at the right side of the power circuitry box on the belly. This can help by cooling down the thermistors on the induction board. There was a very in depth thread where a couple of us put a watt meter on the plug going to the Bullet and measured the wattage that the Bullet was using at different temperatures. If I recall correctly, that was when we found that the logic in the induction board was reducing power to the induction unit.

Aillio, made several updates to the firmware and than seemed to help.

Later, I mounted a computer muffin fan on the bottom with it’s own power supply and switch. I am still using it, but I am not sure how effective it is.

The other area that made a big difference in keeping the Bullet from shutting off was to aim a fan at the area to the right and slightly below the control face. Just adding an external fan dropped the temperature much in just a few minutes.

I took that to a new level and mounted a small fan to force air into the IBTS electronics chamber.

I pulled 5 volts from a USB port on a board and soldered it.

I haven’t had any problems with overheating for a long time now.

My ambient temperature here in Southern California in my unheated garage with no air conditioning ranges from 13C to 35C (55F to 95F)

That’s incredible that you can roast above 90F. My old board used to struggle at 80F with two bigger USB fans going full blast. But the new board almost doesn’t need fans, it runs much better.

Some people say the 220v version doesn’t over heat, but I’d imagine there is no version of electronics that perform optimally with excessive heat. But I have yet to hear of any confirmed over heating on the 220v version.

Looking back, the hottest ambient temperature I have a completed roast for this past summer is 36C. I have several 30C and above. My roasts are in a non-heated or cooled garage this year using a small fan aimed at the box, like in the photo above from @billc . I had one roast shut down on me just before the end, and I can’t recall what the temperature was. It was early September, and I know it did not get to 36C outside that week. I’ve had some trouble getting a roast going at around 0C, but once going it goes.

I remember in one of the threads that there are some roasters that will store their Bullets inside when it is cold and then take it out to the garage to do their roasting. (they weren’t able to start a roast cycle)

I have heard of others directing a small space heater at their Bullet in the garage to get it warmed up enough to run it.

I don’t know, but it is possible that there is something in the firmware that checks for ambient temperature and my keep the Bullet from running when it is too cold.

I also recall seeing mention of a low temperature check. I have a kerosene heater out there now.