I recently redesigned my exhaust setup for the Bullet, including the Pro Cooling Tray.

The main reason is, that the strong cooling tray fan was creating an unwanted side effect. Whenever it turned on, smoke started to push backwards, up into the roaster exhaust pickup and back into the room. At the same time, I noticed that my old inline fan was heavily contaminated with oils and chaff because it had been pulling oily and particle loaded exhaust directly through the fan housing. That was enough to make me rethink the entire construction.

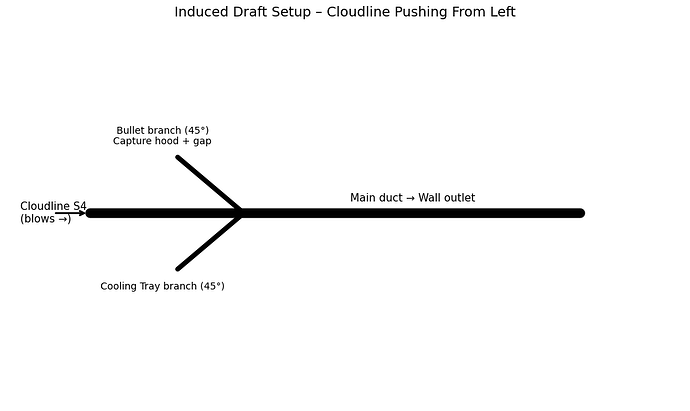

The solution was to switch from a traditional “pull” design to an induced draft setup. Instead of pulling smoke through the inline fan, the fan now pushes clean room air into the main duct that leads to the wall outlet. By blowing with the natural exhaust direction, the injected airflow in the center tube creates a negative pressure zone at the two 45 degree pickup points (branches). One for the roaster exhaust outlet and one for the cooling tray.

The Bullet isn’t rigidly connected, there’s a small gap under the capture hood as suggested by Aillio, so the machine stays freely movable.

This approach solves all previous problems at once:

• The fan stays cool — no thermal stress, much longer lifespan

• No more oil or chaff buildup inside the fan

• No backflow when the cooling tray fan engages

• Smoother, quieter airflow (all fittings are angled with the flow)

• Stable draft for both roasting and cooling

It’s the same principle used in industrial induction hoods: push clean air → indirectly pull the smoke. With a powerful inline fan, such as a Cloudline, this should work pretty well with 100 mm (4”) duct runs.

If anyone is interested, I’m happy to share a proper diagram and part list — and some tuning tips for optimal results with different batch sizes. This setup should bee a noticeable upgrade.

The Infinity Cloudline Fan and the tube with the two branches will be mounted under the table top. This setup should greatlyx enhance the lifespan of the Cloudline fan.