Yes they are under developed likely with a hay or green taste. I have some observations and suggestions that might help and sorry if i write some trivial remarks along:

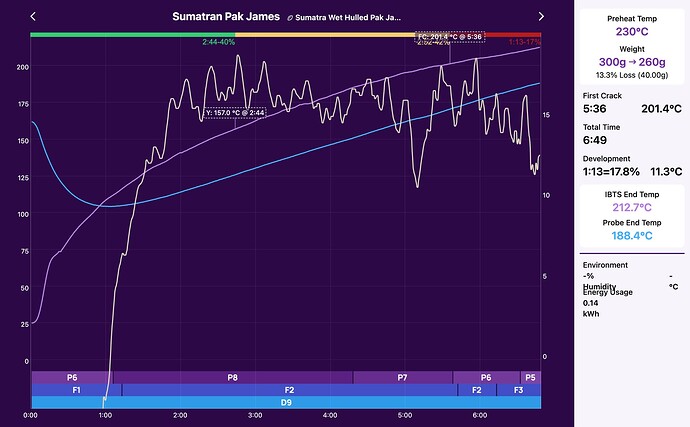

- There is a lot of noise in your RoRs. BTW I suggest roasting with both RoR, from the infrared and from the probe. You will notice difference specially just before first crack.

Solution: Roast with at least 400g. You will have much less noise and more consistent reading to correct you roast afterward. Roasting at D8 also gives more precise readings but D9 seems to be ideal speed for roasting with the bullet.

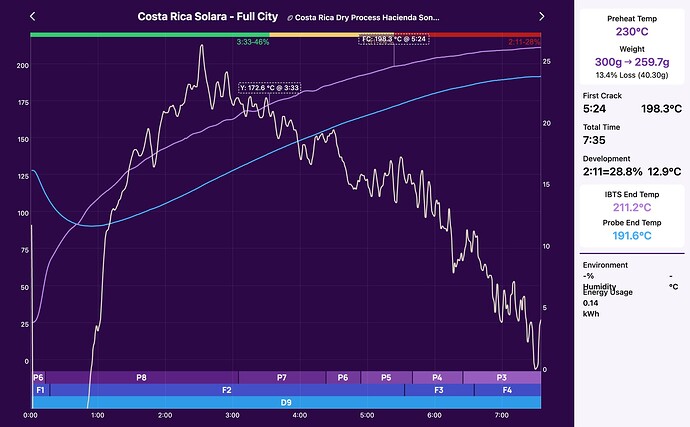

- If i look at first roast, you do not have enough heat/energy transfered to the beans at the beginning. The level of the roast curve is important too not just the shape. You need more convex (than what you have) after the turning point.

Solution: First roast, do not charge after 20 min when it says charge. Pre-Heat 45-50 min at 5 or 10 degree over the targeted charge temperature. Adopt a consistent protocol between batches. Adjust the charging temperature according to the load (i.e. 400g vs 600g) but also the size and density of your beans. This is very important and often overlook. And eventually the moisture contained in the beans (for example 13%= charge higher than 11%). If you do not have any instruments to measure that, ask your provider. He should be able to give you density and moisture. You should also know how the bean was treated (washed vs natural pulped, fermented, etc). Take also note of the ambient room temperature and humidity to reproduce roast eventually. And the temperature of the beans before charging (not the same if 19c vs 23c for example). The bullet is sucking a lot of humidity. It can drop 10% after a roast.

I suspect here that your costa rica is from Tarrazu where they grow up to 1800 meters, very dense beans (likely around 0,73g/ml). You need more heat or at least not cutting the heat too soon.

-The second graph shows different heat absorption. I guess different size, density, moist and cellulose arrangements in the bean structure. Difficult to say without knowing the beans.

My suggestions:

- Start with 400g batches (Try once with a 600g, you will see everything goes slower).

-Start with an easier bean (less dense) to roast, like a Brazilian bean.

-Mostly stick to roasting the same bean often at the beginning

-Clean the infrared before each session (not each roast).

Because of beans differences and also differences between bullet models and even between same models, it is almost impossible to gives sound advice on a specific roast. I put a watt reader on my bullet R1V2 and from day to day at the same P, it draws different watt, so heat is affected.

Anyway if you still want to roast the Costa Rica one I would try that for a light roast with a sweet cup profile.

400g I supposed size 16, density around 0,73g/ml, moist around 12%.

Room: 21-22c , 30% hum

pre-heat: 250c 50 min

Charge: 245c (BT should be around 172-175c if not, rise the charge by 5. If higher than 175c lower the charge by 5).

Start with P8, F3, D9

-Hit F4 when BT around 147-150 (infrared should be around 173-175). Should be around yellowing.

-Hit P7 around infrared 180 (Bt around 160)

-Hit P6 just before first crack (190-195 infrared 175-182 bt probe).

-Hit P5 198-202 infrared(184-190 bt probe)

-Hit P4 205 infrared (194 bt probe)

Then reduces P gradually and until

Infrared 212c Bt probe 204c.

The spread between infrared reading and BT will likely be different on your machine. I would tend to say, do not drop if BT is under 200c if you do not like lighthly under developed notes. Anyway it has not much chance to work given all the unknown factors but basically, you need more heat at the beginning. If above does not work, try briefly going to P9 between 100c and 125c with infrared returning to P8 at 125c infrared.

ps your costa rica is not bake. The batch hasn’t stalled either. It is underdeveloped. You cannot follow any indications using time per say as without kwowing the beans characteristics it does not say much. However, your timeline does not shock me for a light roast.